Introduction

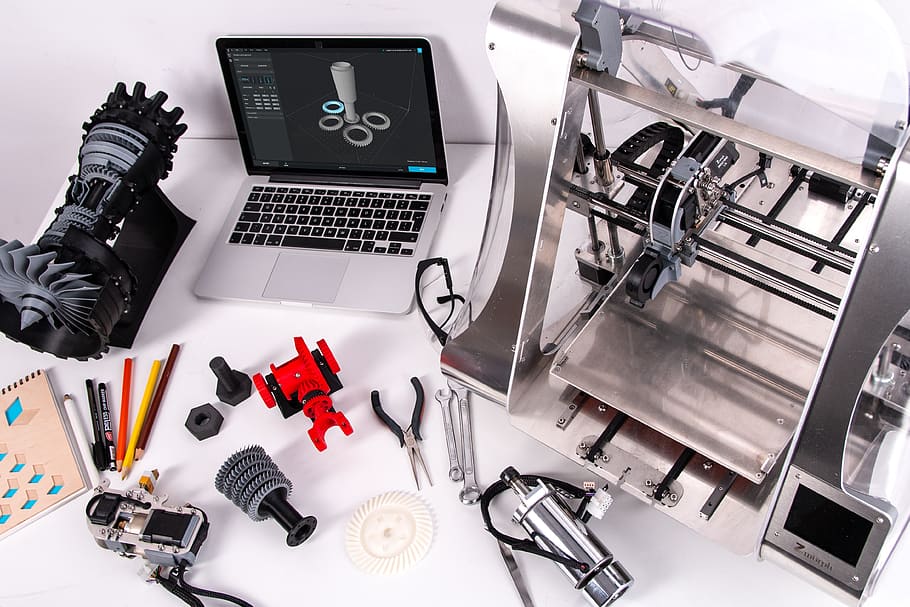

The world of 3D printing has captured the imaginations of engineers, artists, and hobbyists, revolutionizing manufacturing and design. But how does 3D printing work? In this in-depth article, we will unravel the mysteries behind this cutting-edge technology, exploring its history, applications, and the intricate process behind it. Join us as we delve into the world of 3D printing and uncover its power to transform ideas into reality.

Unleashing the Power of 3D Printing: Demystifying the Process Unveiled

What is 3D Printing?

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from a digital file. Unlike traditional manufacturing techniques that involve cutting or drilling away materials from a solid block, 3D printing builds objects layer by layer, adding material only where it is needed. This results in minimal waste, greater design freedom, and the ability to create complex geometries that were once impossible.

Also, check out this article for additional information: 3D Printing: What It Is, How It Works and Examples | Built In

The History of 3D Printing

The roots of 3D printing can be traced back to the 1980s when the first patent for an additive manufacturing process was filed. However, it wasn’t until the early 2000s that 3D printing started gaining traction in various industries. As the technology advanced, the cost of 3D printers decreased, making it accessible to a wider audience.

How Does 3D Printing Work?

Step 1: Designing the 3D Model

The first step of how does 3D printing work is: The 3D printing process begins with creating a digital 3D model of the object to be printed. This can be achieved using computer-aided design (CAD) software or by 3D scanning an existing object. The 3D model serves as a blueprint for the printer to follow.

Step 2: Slicing the Model

The second step of how does 3D printing work is: Before printing, the 3D model is sliced into thin horizontal layers using slicing software. Each layer is a cross-section of the object, and these layers are what the 3D printer will use as a guide to build the final object.

Step 3: Selecting the Printing Material

The third step of how does 3D printing work is: There are various materials available for 3D printing, including plastics, metals, ceramics, and even food items. The choice of material depends on the desired properties of the final object, such as strength, flexibility, or heat resistance.

Step 4: Printing the Object

The fourth step of how does 3D printing work is: The 3D printer starts the printing process by laying down the first layer of material, following the instructions from the sliced model. The printer adds subsequent layers on top of each other until the entire object is formed.

Step 5: Post-Processing

The fifth step of how does 3D printing work is: Once the printing is complete, the object may require some post-processing, such as removing support structures, smoothing the surface, or applying finishing touches to achieve the desired aesthetics.

If you are looking to 3D print the components which you have design then visit this page Best 3D Printing Service | Crenodez Engineering Solutions to get high quality 3D prints from their state of the art 3D printing facility.

Applications of 3D Printing

As we saw how does 3D printing work in the previous section, let us now look further on the applications of 3D printing. 3D printing has found applications in a wide range of industries, revolutionizing the way products are designed and manufactured. Some of the key applications include:

- Prototyping: 3D printing allows rapid prototyping, enabling designers and engineers to test and refine their ideas quickly and cost-effectively.

- Medical: From creating custom prosthetics to printing human organs for transplantation, 3D printing is transforming healthcare.

- Aerospace: The aerospace industry uses 3D printing to produce lightweight and complex components, improving fuel efficiency and reducing costs.

- Automotive: Car manufacturers use 3D printing to create prototypes, custom parts, and even entire vehicles.

- Art and Fashion: Artists and fashion designers are pushing the boundaries of creativity with 3D-printed sculptures, accessories, and clothing.

Advantages of 3D Printing

Design Freedom

With 3D printing, designers are not limited by traditional manufacturing constraints. Complex and intricate shapes can be created without increasing production costs.

Cost-Effective

For low-volume production or custom items, 3D printing can be more cost-effective than traditional manufacturing methods.

Rapid Prototyping

3D printing allows for rapid prototyping, reducing the time it takes to go from concept to a physical product.

Reduced Waste

Traditional manufacturing methods often result in a significant amount of waste material. 3D printing only uses the material required for the object, minimizing waste.

Accessibility

As 3D printing technology becomes more affordable, it is becoming accessible to individuals and small businesses, democratizing manufacturing.

Limitations of 3D Printing

Speed

3D printing can be a slow process, especially for large or intricate objects, which may require hours or even days to print.

Material Limitations

While 3D printing offers a wide range of materials, some specialized materials may not be available for certain printers.

Post-Processing Requirements

Certain 3D prints may require additional post-processing steps to achieve the desired finish, adding time and effort to the overall production.

Quality and Resolution

The resolution and quality of 3D prints may not match the precision of some traditional manufacturing methods.

FAQs

Q: Is 3D printing suitable for mass production?

A: While 3D printing is ideal for low-volume production and prototyping, it may not be as efficient or cost-effective as traditional mass production methods for large quantities.

Q: Can I 3D print objects at home?

A: Yes, there are consumer-grade 3D printers available that allow individuals to create small objects at home.

Q: What materials can be used in 3D printing?

A: 3D printing materials include plastics, resins, metals, ceramics, and even biological materials.

Q: Is 3D printing environmentally friendly?

A: Compared to traditional manufacturing, 3D printing can be more environmentally friendly due to reduced waste and energy consumption.

Q: Are there any size limitations in 3D printing?

A: The size of objects that can be 3D printed is determined by the dimensions of the 3D printer’s build platform.

Q: Can 3D printing be used for architectural modeling?

A: Yes, 3D printing is widely used in architecture for creating detailed scale models and prototypes.

Conclusion

Unleashing the power of 3D printing has transformed industries and empowered creative minds to bring their ideas to life. The process of 3D printing, once shrouded in mystery, has been unveiled, and its potential is boundless. As technology continues to advance, we can expect even more exciting applications and innovations in the world of 3D printing. So, whether you’re an engineer, artist, or simply curious about this transformative technology, take the plunge and explore the world of 3D printing for yourself.

If you are looking for high quality 3D printing service, you are highly recommended to visit Best 3D Printing Service | Crenodez Engineering Solutions